Key investments in bespoke manufacturing hardware & real-time proprietary software to progress Process Digitisation and aid Customer Efficiency.

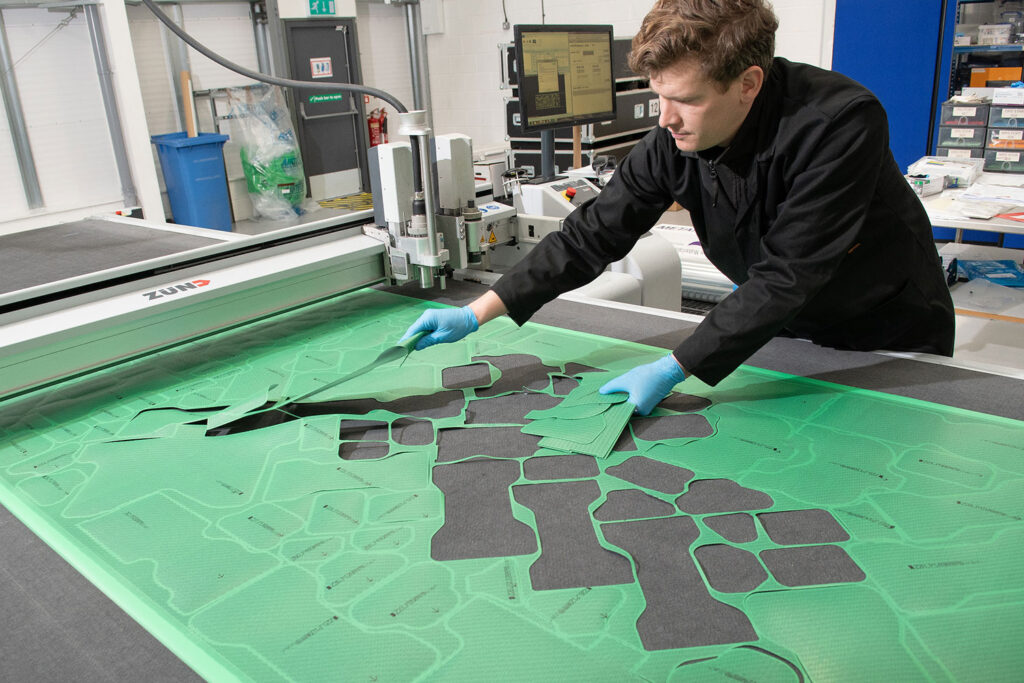

- 13 state-of-the-art 3-axis cutting machines & printers, together in global partnership with Zund Systemtechnik AG, driven by Velocity proprietary software.

- Digital Manufacturing Cell incorporating vision systems for each cut shape, pick-by-light systems to augment kitting operation which provides real-time visual status on progress.

- Proprietary laser cutting & perforation equipment for contact free manufacture of delicate process materials.

- Proprietary stitching, thermal welding and ultrasonic welding equipment to produce complex 3D breather & vacuum bag assemblies.

- RFID supported real-time monitoring of raw material location and product life throughout the kit manufacturing lifecycle

- Cleanroom’s built and operated to at least ISO Class 8 standards.

- HypernestTM proprietary production & material nesting software, directly integrated into Velocity’s cutting machine via our VRPTM system with a dedicated engineering and process optimisation team.

- VRPTM digital real-time management of supply chain, demand, manufacturing & delivery processes to aid efficiency and provide visual status feedback to Customers.

- Cut shape level real-time traceability provided through integration of Velocity’s proprietary software developments.